The vibrating screen is a common part of every screening equipment, and it is used for reducing the size of different raw materials. The vibrating screen consists a rigid frame, a motor, an eccentric bock and one or several screen surfaces. It is well known that the vibrating screen is the most stable piece of screening equipment, an essential tool for the mining industry. Also, the vibrating screen is highly efficient tool that use less fuel. Mainly used in the mining, electric power, construction and chemical industry, the vibrating screen is considered as unique tool due to its design and structure.

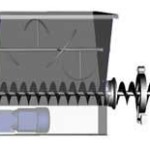

The vibrating screen works by the principle of high-speed rotation. It is composed of a screen box, a sieve plate, a vibrator, a liner, under-frame and a screen mesh. To adjust the amplitude, the vibrating screen uses a cylinder eccentric vibrator shaft and an eccentric block. The vibrator is positioned on a steel-made sideboard, and is driven by the motor of the vibrating screen. To make the screen box vibrate, the vibrator generates a centrifugal force.

Although there are many different vibrating screen models, they all use the same and unique working principle. The most popular vibrating screens are: inertia vibrating screen, single-deck vibrating screen and the eccentric vibrating screen.

When the vibrating screen works, its eccentric shaft rotates continuously. The screen box rotates relying on the vibration motor, causing the whole unit to vibrate linearly supported by the absorber. As the unit vibrates, the material enters the screen box from the feeding port at the top of the vibrating screen and moves through few stages of the screening process. The absorber system is made from rubber spring, lathedog, operator’s supporting seat and many other supportive features.

As the screen rises with the movement of the eccentric arm up, the materials in the vibrating screen become loose. But when the screen falls with the movement of the eccentric arm down, the thrown materials fall down to the screen surface. The materials that meet the desired requirements by the operators can go through the screen, while the materials that do not meet the expected requirements are being discharged immediately. This way, the contractors can get the desired size of the materials.